Stronger, non-flammable polyester fabrics

A new additive improves the production of polyester for textiles.

Additives can make artificial fibres more resistant. | Image: Empa.

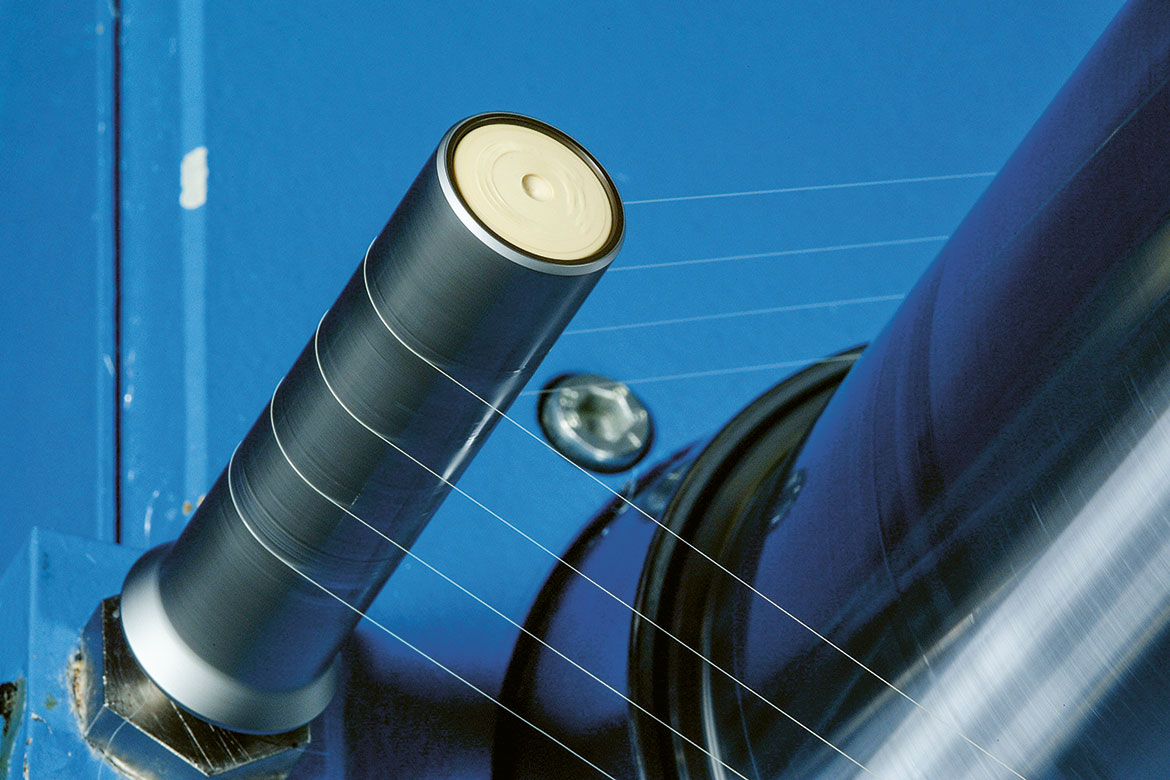

A team from the Federal Laboratory for Materials Science and Technology (EMPA) has developed a new additive for polymers of polyester textiles. It should improve manufacturing processes and make them more resistant and flame retardant. Currently the polymers are heated to over 280º Celsius, and, once the desired level of fluidity is reached, they are spun by an extruder into the fibres that are woven or combined with other materials such as cotton.

“The heating part of the process normally affects the molecular structure of fibres and reduces the resistance of the textiles produced from them”, explains Manfred Heuberger, a researcher at EMPA. So he and his team looked for a fluidiser that would allow polyester to be spun at a lower temperature. This would obtain more robust textiles whilst also reducing the energy costs of production.

Scientists have synthesised and patented a phosphorous fluidising additive. When added to the molten polymer, it lowers the threshold temperature by a few degrees and also gives the textile flame-retardant properties. The prototype fibre has a mechanical resistance approximately 40 percent higher than that of the best existing flame-retardant polyester.

The researchers studied the fluidification aspect of the compound in collaboration with the company Tersuisse. The potential is for a fireproof and highly resistant fibre, mainly intended for architectural usages such as shutters and signs. “Although the process has proved its worth in the laboratory, industrial developments are still in their infancy”, says Niklaus Zemp, the managing director of Tersuisse. “Our tests must be conclusive and, above all, the additive must be producible on an industrial scale and at a reasonable price”.