MECHANICS

Get into the groove

Rotors of decentralised electrical generators can be mounted on a layer of gas. A research group at EPFL has been optimising their rotational speed.

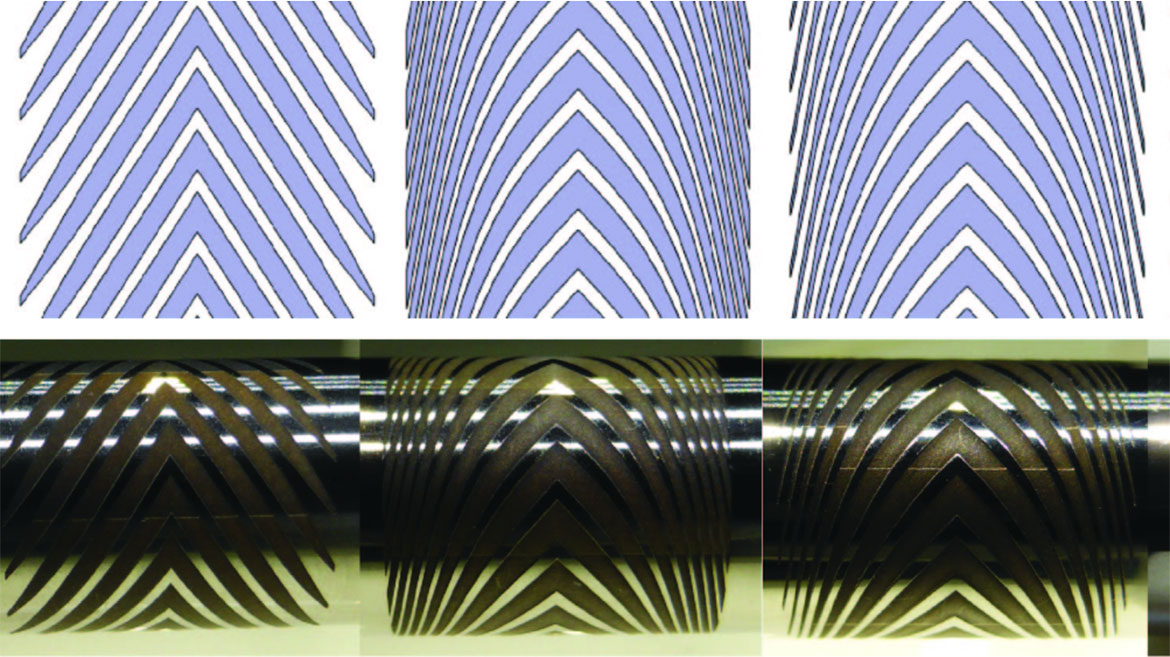

Three different groove profiles for improving the speed of rotors. | Image: P. K. Bättig et al. (2022)

Decentralised electricity production needs small-scale, high-speed turbomachinery. Rotors can be mounted on a layer of gas instead of ball bearings, and their stable running ensured by herringbone-shaped grooves in the rotor. Calculations made by Jürg Schiffmann’s research group at EPFL have improved the stability of this machinery even further by optimising the shape of these spiral grooves. Practical tests have confirmed this. By varying the angle, depth and width of the grooves, the maximum stable speed of the rotors increased from 56,000 to 180,000 revolutions per minute.