REPORT

Big blue

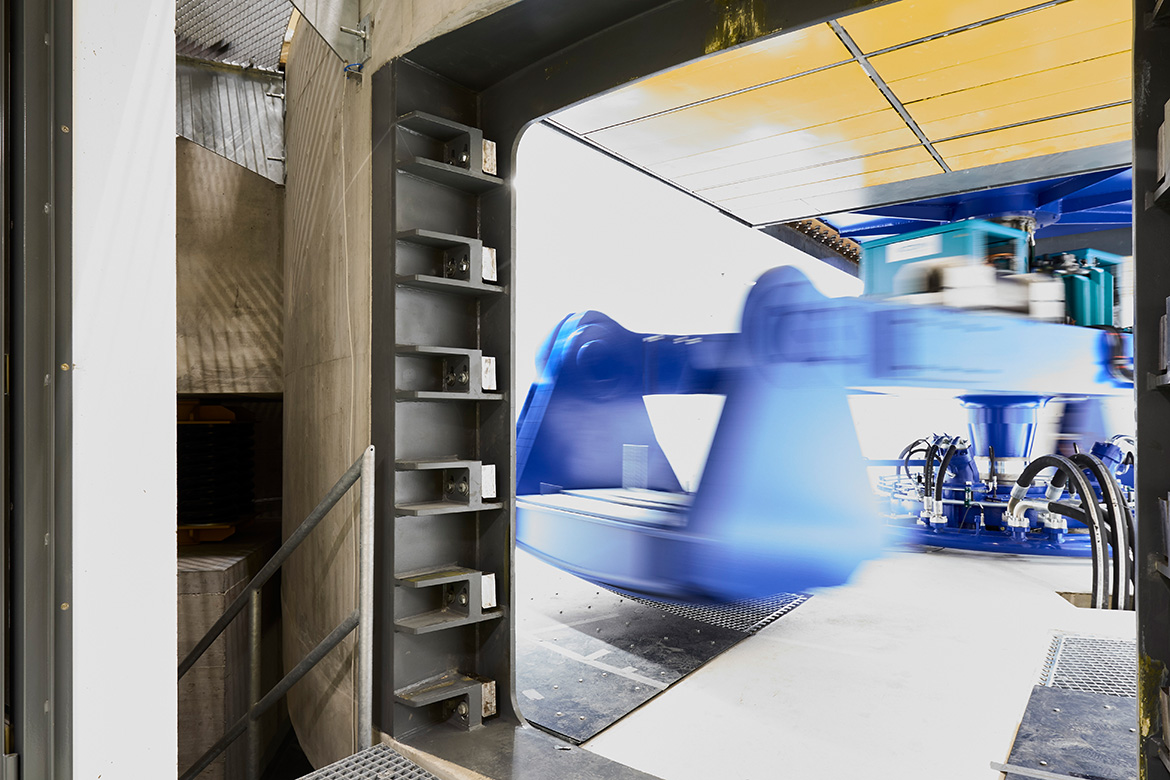

The research centrifuge with the highest capacity in Europe has been in operation at the ETH Hönggerberg campus since June 2023. It’s being used to investigate the effects of earthquakes and floods on buildings, bridges and dams.

The centrifuge is still rotating very slowly here. When it runs at full power, the doors are closed. The experiments it can carry out include testing the impact of an earthquake on certain soils. | Image: Markus Bertschi

Elegant, futuristic and a luminescent blue, ETH Zurich’s new research centrifuge floats almost weightlessly in space. It’s enclosed in a concrete housing weighing 245 tonnes, and it’s now ready for its first experiments. We’re several metres below ground at the ETH Hönggerberg Campus in the north of Zurich, and Europe’s most powerful research centrifuge is finally ready for use after seven years of organising, building, renovating and testing. The yellow steel door to the centrifuge chamber provides a nice colour contrast, but is purely practical and weighs several tonnes itself.

Since June 2023, models weighing up to two tonnes can be accelerated in this centrifuge up to 250 g – that’s 250 times the Earth’s gravity. “But we won’t be running the centrifuge at its limit”, says Professor Ioannis Anastasopoulos. He’s the head of the Geotechnical Centrifuge Center at ETH Zurich. “Our experiments are mostly conducted in the 100 g range”, adds Ralf Herzog, who’s responsible for the technical installation and has to make sure all the systems run smoothly.

All the same: when the centrifuge picks up speed and is spinning at some 250 km per hour, it’s still scary. Its hydraulic oil pumps alone make an immense racket – they generate 1,000 hp.

Heavy lifters had to be brought in even before the centrifuge itself was actually installed in its specially converted wing of the Hönggerberg Campus. Three years ago, Switzerland’s biggest crane lifted the concrete housing of the centrifuge into the pit that had been excavated for it. This housing rests on four specially designed steel springs and constitutes the centrifuge’s foundations. When the centrifuge itself starts to spin and unleashes its power, the springs and the concrete housing soak up the smallest vibrations and isolate them from the outside world. This means that none of the highly sensitive experiments in the neighbouring laboratories are in any way affected.

It took a year to install this 20-tonne beam centrifuge. It had previously stood for years in a storage facility in Bochum, after having served researchers there for 20 years. It has since been restored extensively. “When we first saw it, I didn’t think it would ever run again”, admits Herzog. “Apart from its massive steel beam, almost everything about it is new: all the bearings, motors, hydraulics, electronics and sensors have been reconditioned and modernised”. Now they can begin their experiments.

100 times smaller, but 100 times heavier

“We are currently using it to simulate soil-structure systems”, explains Anastasopoulos. “These are structures that are anchored in the ground, such as a building’s foundations, a dam or a bridge”. One good example would be a bridge that is anchored with several columns in a liquefiable soil. It is difficult to analyse how the ground and a building standing on it will behave in an earthquake, for example. “We can’t build a layer of soil that’s 30 metres thick here in the lab. We have to scale it down and work with models”.

There’s a problem here, however. The weight plays a decisive role in the interaction between the ground and the structures in and on it. “The research centrifuge lets us solve this problem thanks to artificial gravity”, says Anastasopoulos. When the roughly nine-metre-long rotating arm is spinning at 148 revolutions per minute, the force of gravity exerted on the prefabricated model is 100 times normal. This means that the model can be 100 times smaller and lighter than would be the case in the real world. This balances out the weight, the forces involved, and the load.

Anastasopoulos and his team want to use this centrifuge to gain a better understanding of various issues, such as the impact that earthquakes have on buildings. “The soil has a big influence on how much seismic acceleration a building can withstand”, he says. “Regrettably, we’ve recently seen this again in Turkey”. Depending on the geology of the area in question, seismic waves will change the properties of the soil and exert utterly different effects on the buildings standing on it. In Turkey, some buildings collapsed because they were tossed from left to right as if in a cocktail shaker. Others sank almost undamaged alongside them because the soil beneath them essentially liquefied. “How a structure reacts to an earthquake depends immensely on the soil. This is something that our centrifuge can help us investigate and understand better. It will help us to provide more safety during earthquakes”.

Another field of application for the centrifuge is the study of tsunamis and flood disasters. “In such events, structures and their foundations often fail because the seabed or the riverbed are washed away in a short space of time”, says Anastasopoulos. With the aid of a special apparatus, the centrifuge at Hönggerberg can simulate a continuous flow of water like the one that led to the disastrous floods in Germany in 2021.

20 earthquakes per minute

“It’s the preparation that requires the biggest efforts when you’re doing an experiment”, says Anastasopoulos. “The models have to be constructed precisely and meet specific parameters so that we can use them for the simulations”. A machine made especially for the task piles up the sand that is to serve as a soil model. There has to be precisely the right amount of soil, weighing the right amount, and of the right density. The 3D-printed models of bridges and foundations are checked in advance for their structural comparability. Even the water that’s used in the model is special: it comprises a highly viscous mixture of water and methyl cellulose that will behave exactly as needed when subjected to the high g force.

Only once everything has been prepared can they place the model on one of the two arms of the centrifuge. It takes 10 to 15 minutes for it to reach the required velocity. During this time, the model slowly moves from the vertical to the horizontal. The centripetal acceleration is essentially pressing it towards the wall. Then come the earthquake simulations that are created by the shaking table on which the model stands. This is a unique construction that allows the research team to generate ‘earthquakes’ a hundred times quicker than in the real world and on a scale a hundred times smaller.

“This equipment was especially made for us, because the vibrations we need have to be very fast and very small”, says Anastasopoulos. “An earthquake that lasts 30 seconds in reality can be simulated here in 0.3 seconds”. The measuring devices employed have to be accordingly sensitive – including the cameras that document what’s happening in the centrifuge. “A normal high-speed camera might take some 10,000 pictures per second”, says Herzog. “But ours manage up to 10 million images per second”.

There is hardly anywhere else that offers this combination of centrifuge and shaking table that exists at ETH Zurich. To be sure, in Japan – which is particularly susceptible to earthquakes – you can find huge earthquake shaking tables on which researchers can test the static stability of five-storey buildings. And larger centrifuges exist elsewhere too. But it is the combination in Zurich that makes the magic happen. “Thanks to this centrifuge, we can simulate soil thicknesses of 40 metres. This would be impossible or far too expensive to realise with ordinary shaking tables”, says Anastasopoulos.

Less cement and greater security

Anastasopoulos also wants his centrifuge research to make a contribution to combating global warming – though he is not too fond of the phrase, or of the other buzzwords that are bandied about in the world of science and politics today. “Our research can help us to optimise the earthquake resistance of buildings”, he says. “This can enable us to reduce the consumption of climate-damaging cement and steel when restoring bridges or building new dams”. This can reduce both a project’s costs and its ecological footprint.

On the other hand, global warming is increasing the frequency of extreme events such as flood disasters. “This is why the foundations of bridges and dikes are being exposed to far more powerful washout processes”, says Anastasopoulos. “We can simulate these in our centrifuge and thus optimise adaptation measures”. Cyclical and long-lasting pressures can also be simulated in the centrifuge – e.g., the back and forth of the waves that exert pressure on the foundations of offshore wind power plants. “With our research, we can do something concrete to combat global warming”.

These practical aspects were what triggered Anastasopoulos’s fascination for geotechnics, almost 30 years ago now. Back then, an earthquake measuring 7.3 on the Richter scale shook the centre of the city of Kobe in Japan. Many bridges collapsed, more than 60,000 buildings were completely destroyed, and 6,500 people died. “I was a student in Greece back then, and I was fascinated by the impact and the damage that resulted from the interaction between the ground and the buildings”.

Anastasopoulos still goes to Japan with his students almost every year to exchange ideas with researchers on the ground. “Earthquake safety is an optimisation issue in Switzerland”, he says. “But for countries like Turkey and Japan, it’s a matter of survival”.