REPORT

The rest is nano-silence

In Rüschlikon, the concept of ‘peace and quiet’ has achieved a new dimension. Here, six special laboratories offer conditions of silence that you can find nowhere else in the world. This is vital for cutting-edge research into nanotechnology.

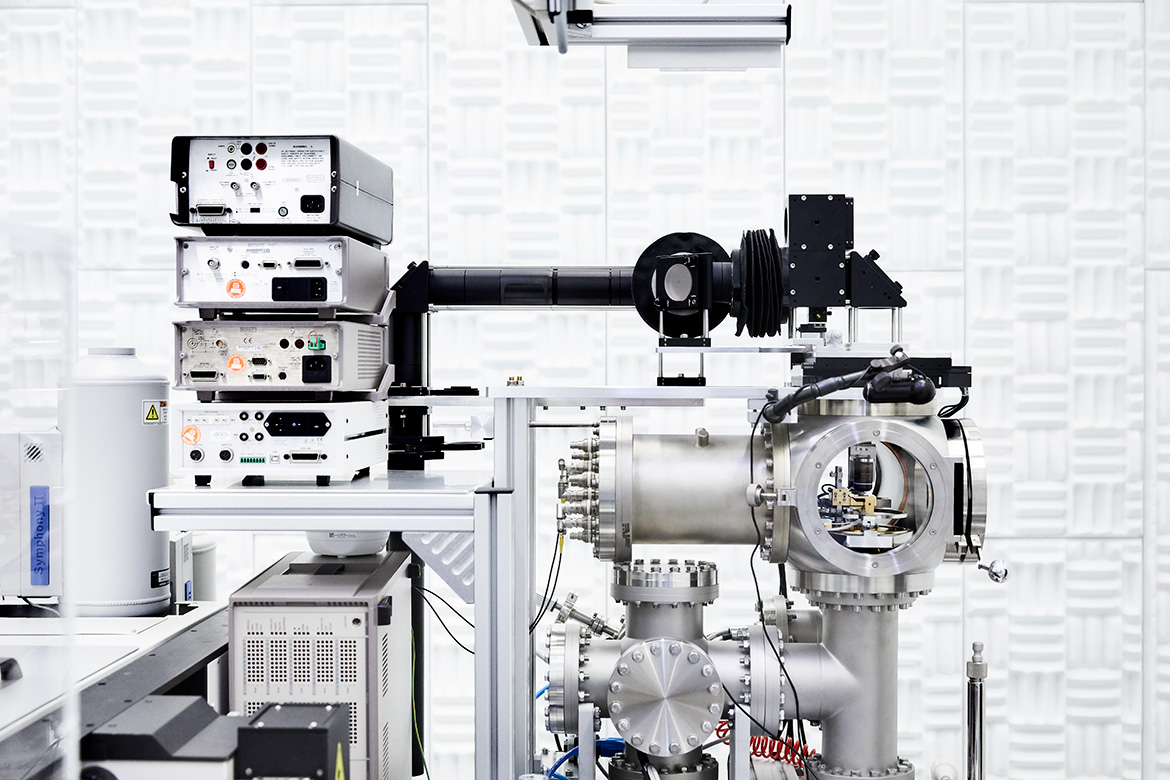

This ultra-high vacuum system allows Emanuel Lörtscher and his team to measure the scattering of light on molecules. | Photos: Lea Meienberg

When you arrive at this place where world records are written, you are greeted by unadorned, functional architecture. The only concession to the senses would seem to be a pond and a few little patches of lawn between the buildings. The IBM Research Lab in Rüschlikon was built in the 1960s. Nothing on the outside suggests that it harbours laboratories within it, eight metres below ground, that send researchers all over the world into raptures. Here, in collaboration with ETH Zurich, the IT giant runs the Binnig and Rohrer Nanotechnology Center (BRNC), named after the physicists Gerd Binnig and Heinrich Rohrer who won the Nobel Prize in 1986 for developing the scanning tunnel microscope here in Rüschlikon. It was this microscope that enabled humans to visualise atoms for the first-ever time. “It can be regarded as the beginning of nanotechnology”, says Emanuel Lörtscher, who was responsible for designing and building the ‘Noise-Free Labs’ that began running in May 2011. The nanotechnology pioneers of the 1980s could hardly have dreamed of the research conditions that are on offer today, high above Lake Zurich.

Initial doubts

In order to grasp the uniqueness of this project, you first have to put all your common-or-garden notions of ‘noise’ behind you. We usually associate the concept with acoustic disturbances – like a lawnmower, a screaming baby or an air-conditioning unit. In order to exclude such sources of noise, it would usually suffice to build a soundproof room. But this is not nearly enough if you want to carry out measurements in the nanometre range. Besides acoustic noise, there are other sources of disturbance such as electromagnetic fields, fluctuations in temperature and air humidity, and seismic vibrations. They can all compromise the results and functioning of the highly sensitive instruments that are employed in nanotechnology. Even before the IBM team got to work, assorted concepts existed that were reliably able to exclude individual disturbance factors. There was the Faraday cage, for example, which serves to keep out electromagnetic radiation. But in Rüschlikon, the plan was to create a holistic shielding concept – a veritable nanotech Garden of Eden. “We wanted a research environment in which the experiments themselves are the biggest disturbance factor”, says Lörtscher. The conditions in Rüschlikon were hardly ideal. The railway tunnel from Thalwil to Zurich and the A3 motorway are less than 200 metres away, and make the ground vibrate. And the railway, mobile radio transmitters and powerlines all emit interfering frequencies. “Everyone said that a concept like ours would be impossible to realise because the shielding measures then known would usually engage in mutual negative influence”, says Lörtscher. “There were no commercial solutions for what we wanted. So it became a research project”.

A hovering, concrete base

The manufacturers of measuring and fabrication equipment in nanotechnology determine under what conditions their products will function optimally – regardless of whether or not laboratories actually exist that can fulfil their criteria. “There are sometimes parameters that the manufacturers don’t know so precisely, but which they can only guess, based on certain well-functioning locations”, says Lörtscher. The ever-increasing demands made by such equipment were among their reasons for embarking on their ambitious project. “For the project development phase, we chose our own most sensitive experiments and utilised commercial equipment that made the highest demands. The laboratories would have to satisfy these requirements for two to three decades”. At that point, the researchers knew the destination of their journey, but not yet how they would actually get there. It took three years until all six labs were up and running. Some participating companies abandoned the project because they were not prepared to issue the guarantees that were required of them. Initially, Lörtscher’s team put two prototype labs into operation and tested them extensively. “I annoyed a lot of people”, he recalls, “because I always tested all proposals rigorously and cast doubt on a lot of things. I had sleepless nights”. On the day we visit the labs, there’s no hint of all that. Maintenance work is currently being carried out, so the labs are freely accessible. There is no daylight in the subterranean corridor that leads to the research labs, but you still don’t get any sense of unease such as you might expect, given that you’re about to enter a place where you are completely cut off from everything. When you get out of the lift, what strikes you is the almost aggressively green colour of the walls. The white-grey colour of the labs is almost a relief after that. Lörtscher opens the massive, magnetically shielded, soundproof door to one of the labs. Inside, it’s unspectacular. It’s almost like a machine room – except that everything is quiet. The high walls are lined with sound-absorbing foam elements – rather like in a concert hall. But this is only the visible surface. Every room is also covered with a nickel-iron alloy that keeps out magnetic fields. At the heart of each laboratory is a concrete base that is almost two metres thick and hovers on a cushion of air above the building’s foundations and the Nagelfluh conglomerate underneath them. Although these concrete blocks weigh up to 70 tonnes each, you can move them easily because they float on air – as Lörtscher demonstrates playfully with a nudge of his foot. The experimental equipment in the labs is all situated on these blocks. The ventilation system means that almost no air turbulence occurs, and the air conditioning in the room is pleasant and barely audible. This is because the floor tiles have holes in them that allow air to enter the room from underneath; this air is controlled as it passes evenly through the room, and is then let out through the ceiling. So you feel fine when you’re in the lab – though in fact it wouldn’t matter anyway, because the researchers all run their experiments from outside it. Human beings sweat, breathe and move about, which makes them disturbance factors too. All the additional equipment such as vacuum pumps, transformers and power supplies are banished into a separate operating room. “From the very start of our work, it was clear that there had to be a spatial separation between the sensitive parts of our experiments and the peripheral equipment that could disturb them”, says Lörtscher.

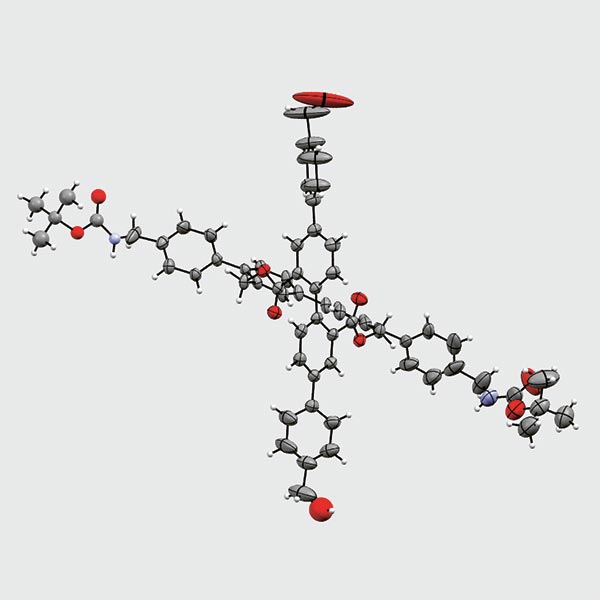

Stasis brings progress

As a result, the vibration levels in their lab are at a world-record low. “At the same time, we are able to achieve a very low noise level of less than 28 decibels, which is barely perceptible to adults, and temperature fluctuations of less than 0.01 degrees Celsius”, says Lörtscher. When the BRNC was opened in 2011, it caused a stir in the science world. Science journalists from all over the world reported on these new ‘chambers of marvels’. Since then, things have calmed down. “Not every paper mentions that its work was done here, or was made possible by our labs”, says Lörtscher. But a lot of research groups are active here today, and IBM is involved in some of them only inasmuch as these labs are ours”. Lörtscher is especially proud of an electron-beam lithography system that is installed in one of the six labs. “It’s essential for nano-research”, he says, “because it lets you write the tiniest structures onto smooth surfaces such as silicon or glass”. This apparatus plays a crucial role in producing test structures for quantum computers and applications in the realm of artificial intelligence. Lörtscher doesn’t have sleepless nights about his labs any more. After nine years, the labs are now well integrated in the BRNC. “At the beginning, we did sometimes wonder whether we had set ourselves goals that were too ambitious”, says Lörtscher. “But it became clear that the extreme demands we were making were the right ones. We can reproduce results time and again under exactly identical conditions”. It’s not a little paradoxical; this place where the technology of the future is emerging is actually a place of complete stasis. It’s almost unreal. There are reports of people panicking in environments like this. “I’ve also read things like that”, says Lörtscher. “But they were written by people who’ve never been here”. He himself is researching into nano-optics that can help determine the composition of materials unambiguously. “This is a technological environment, not some wellness oasis”, he says. “But for a researcher, there’s nothing better”.